Introduction of Fluoro rubber O-rings

Jun 18, 2020|

Jun 18, 2020| View:363

View:363Introduction of Fluoro rubber O-rings

Fluoro rubber O-rings is a kind of rubber seal ring with circular section. Because its section is O-ring, it is also called O-ring. It began to appear in the middle of the 19th century, when it was

used as a sealing element of steam engine cylinder.

Because of its low price, simple manufacture, reliable function and simple installation requirements, O-ring is the most common mechanical design for sealing. The O-ring bears tens of

megapascals (kilopounds) of pressure. O-rings can be used in static applications or in dynamic applications where there is relative motion between components, such as the shaft of a

rotary pump and the piston of a hydraulic cylinder.

Fluoro rubber O-rings is a kind of sealing element with circular cross-section. It is widely used in a variety of mechanical equipment and plays a sealing role in a certain temperature,

pressure and different liquid or gas media. Compared with other sealing rings, it has the following advantages:

① The sealing part has simple structure, compact installation part and light weight.

② It has self sealing function, and can complete the sealing effect with only one seal.

③ Good sealing performance, almost no leakage when used as fixed seal, and some leakage when used as moving seal only when the speed is high.

④ The friction resistance of the movement is very small, and it can also adapt to the occasion of alternating pressure.

⑤ The size and groove have been standardized, the cost is low, the product is easy to get, and it is easy to use and purchase.

Compared with other sealing rings, there are three problems:

① The friction resistance during starting is large.

② when it is used as the seal of pneumatic device, lubricating oil must be added to prevent abrasion.

③ The machining dimension and precision of coupling parts, such as moving surface, groove and clearance, are strictly required.

Structure design principle of fluoro rubber O-rings

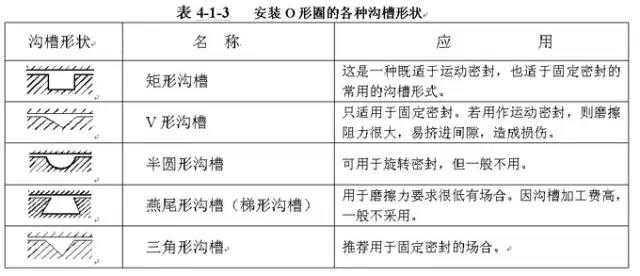

Because the fluoro rubber O-rings is installed in various grooves, the installation groove is listed in table 4-1-3.

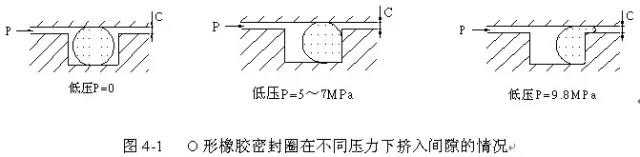

Pressure and seal clearance

Generally, the fluoro rubber O-rings is sealed by the rebound produced by compression, but with the increase of pressure, it is squeezed into the sealing turbid gap to produce shape

change, as shown in Fig. 4-1

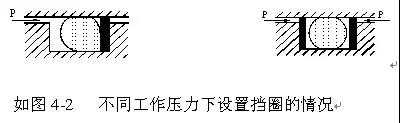

In order to make the fluoro rubber O-rings have good sealing effect and prolong its service life, the gap design of the installation groove and the sealing part of the fluoro rubber O-rings

must be appropriate. When the gap is too large, the fluoro rubber O-rings will squeeze the gap under the action of oil pressure, resulting in damage and leakage. When the working

pressure is less than 9.8MPa, the retaining ring is generally not designed. When the pressure is greater than 9.8MPa, the pressure bearing surface of the fluoro rubber O-rings is easy

to be extruded, and the retaining ring should be added. If the pressure is unidirectional, one retaining ring should be set on the pressure bearing surface, and if the pressure is bidirectional,

two retaining rings should be set, as shown in Figure 4-2

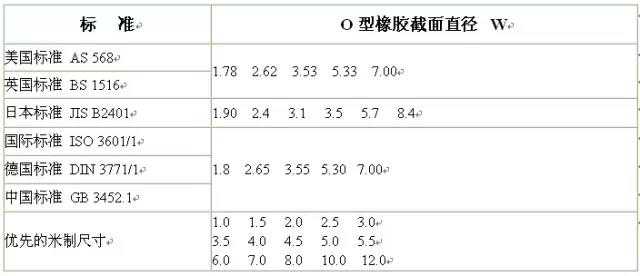

Fluoro rubber O-rings executive standard

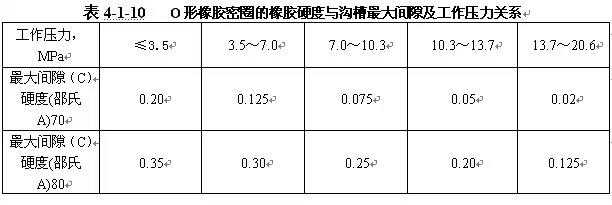

The relationship between the hardness of fluoro rubber O-rings and the maximum gap and working pressure of groove

The size of sealing clearance is related to pressure grade, rubber hardness and diameter of fluoro rubber O-rings section, as shown in the following table:

Depth of groove in piston rod seal

Depth of radial seal groove

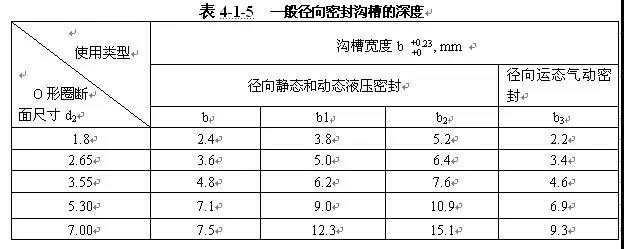

General radial sealing groove width; see table 4-1-5

Width and depth of axial groove of fluoro rubber O-rings with different sections

See table 4-1-8 for width and depth of axial sealing groove

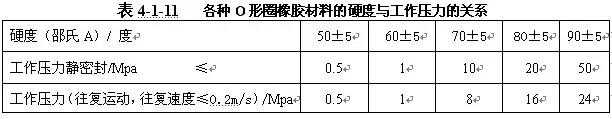

Relationship between hardness and working pressure of O-ring rubber material

In the rubber material standard, hardness and compression set are the two most important properties. The selection of rubber material with smaller compression deformation is beneficial

to the sealing performance, and the hardness is very important for the pressure resistance and extrusion resistance of the fluoro rubber O-rings. According to the domestic standards and

practical experience, the maximum compression permanent deformation of rubber at the specified temperature shall not exceed 50%. The hardness of rubber is closely related to the

sealing working pressure. The higher the pressure is, the higher the hardness is. See table 4-1-11

Note: generally, the working pressure of rotary motion shall not exceed 0.4 MPa, and the hardness shall be (70 ± 5); if it exceeds 0.4 MPa, it shall be designed as a special sealing device.

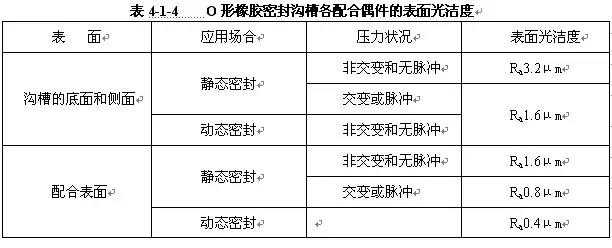

Groove finish requirements

The smoothness of groove and the roughness of groove contact surface have great influence on sealing effect and durability.

Surface finish of mating parts of sealing groove

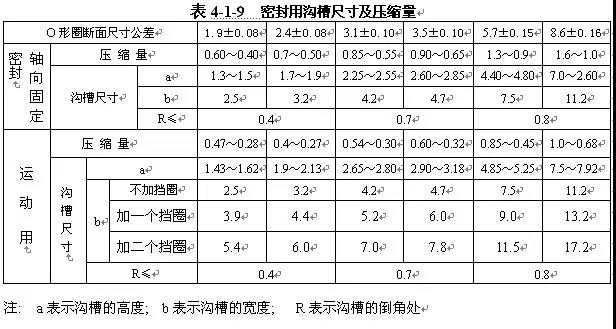

Groove and compression

The compression rate of fluoro rubber O-rings for fixed seal is generally 15-25% (this data is empirical data), 10-12% for moving seal in reciprocating motion, and 3-5% for rotating seal.

See table 4-1-9 for the compression amount and groove size of commonly used fluoro rubber O-rings